The OEM Partner of Choice for Transformer Manufacturers

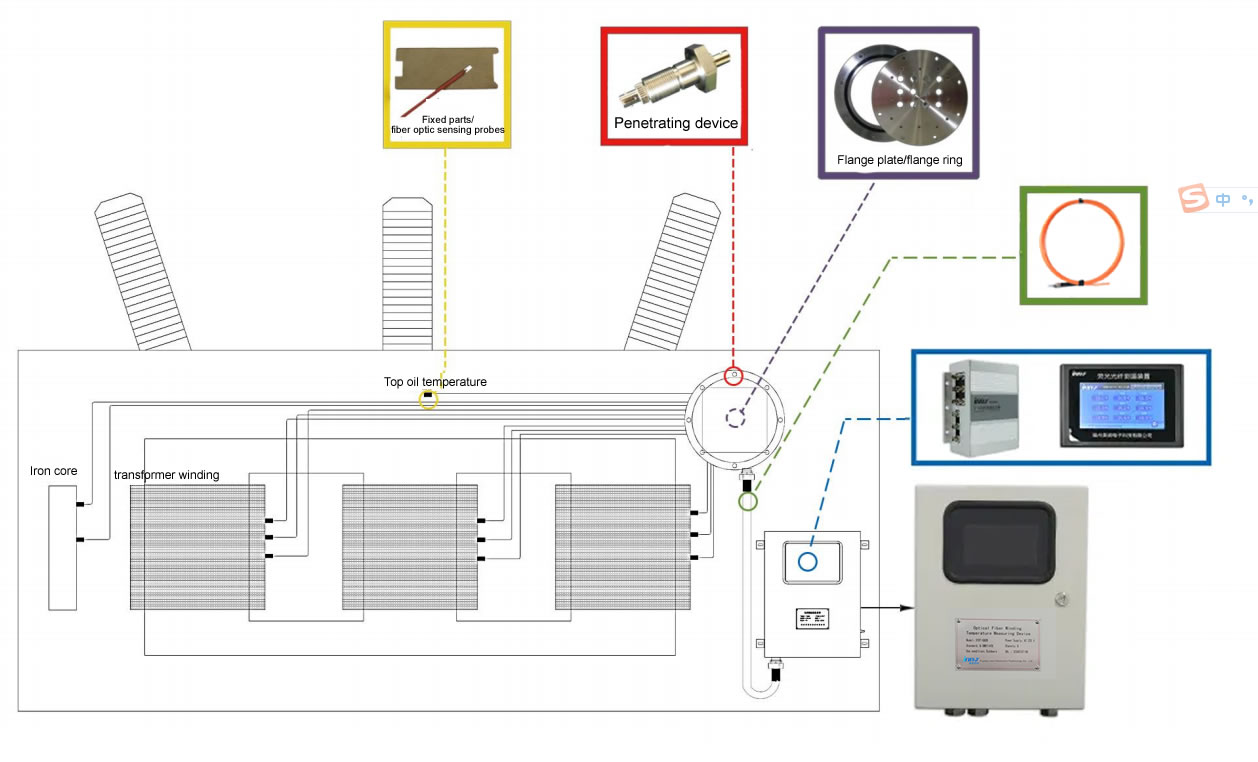

Integrate the industry's best transformer temperature monitoring technology directly into your products. As a dedicated manufacturer and supplier, we offer comprehensive OEM / ODM and private label programs to help you deliver true transformers with digital monitoring.

Partner with us to add significant value, enhance safety, and create a powerful competitive advantage for your transformer offerings. We support you with everything from engineering and integration to wholesale pricing.

Become a Partner